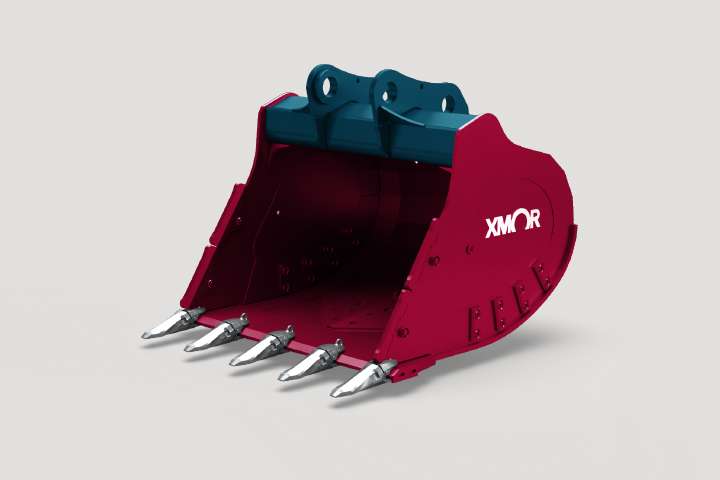

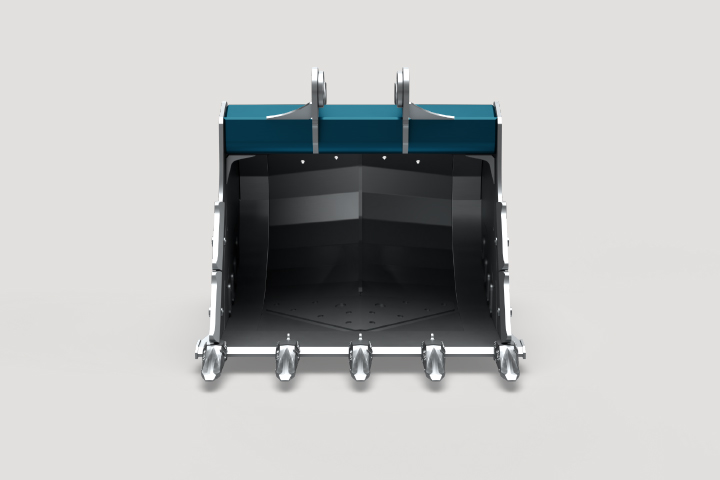

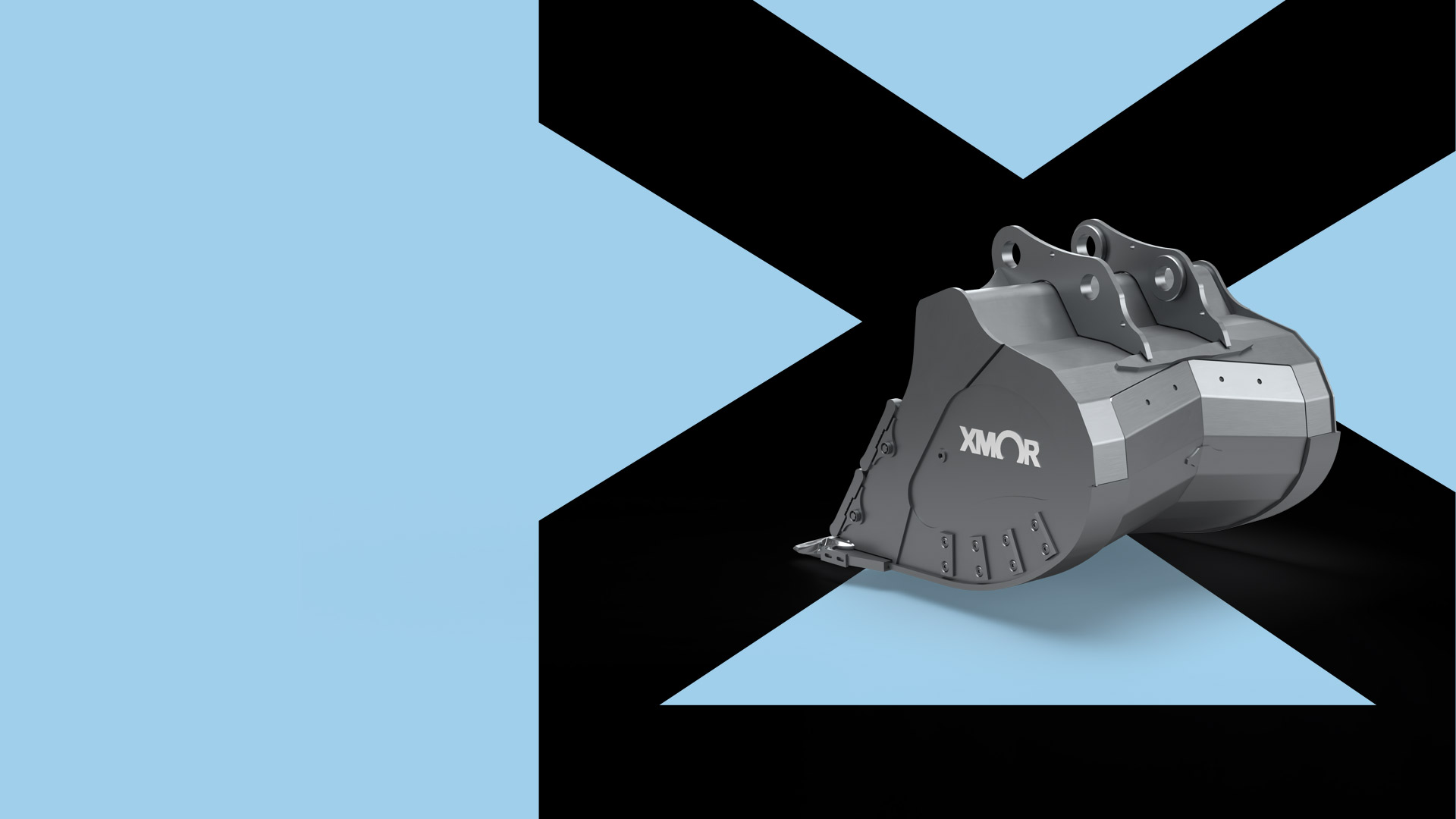

Get an edge in excavation with the XMOR® BHX bucket

XMOR® BHX bucket is built to give up to 15% higher payload capacity compared to a conventional bucket. This bucket targets 50 tonne excavators where increased productivity in digging brings more value to the process.

Get it now Download flyer International (English)

International (English) South Africa (English)

South Africa (English)