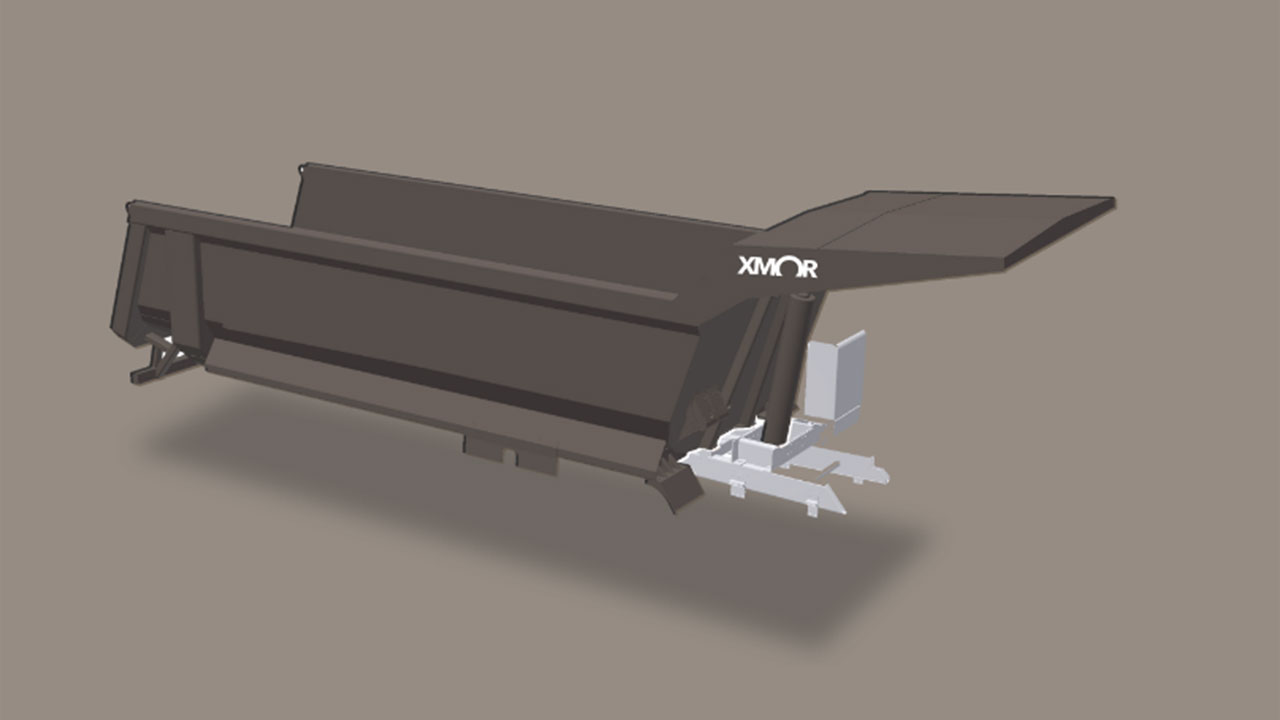

XMOR™ Mining tipper bodies Expect more in less time

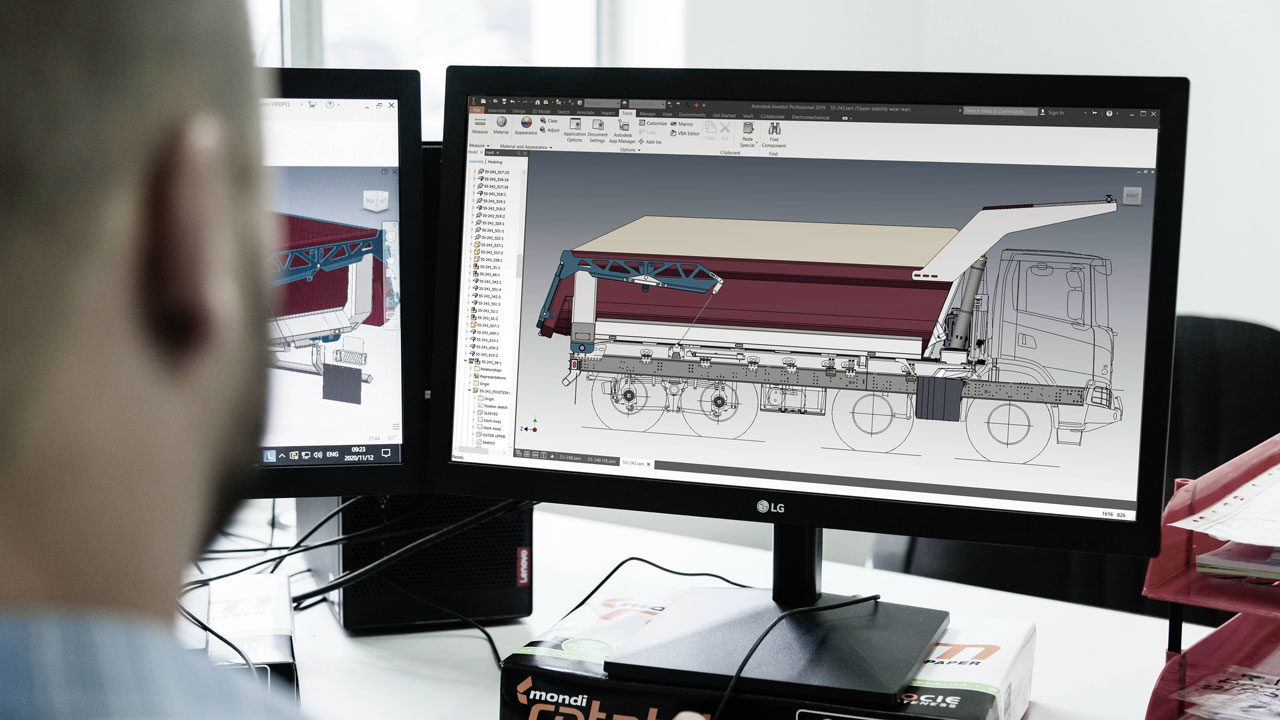

The combination of high-strength steel and innovative design resulting in the lightest tipper body with the highest payload available for the mining and earth moving industry.

IMPROVE YOUR PRODUCTIVITY WITH XMOR™ International (English)

International (English) South Africa (English)

South Africa (English)